Galvanized and stainless steel are two different types of materials that are commonly used to make wires and a variety of other products. However, because both are phenomenal options, knowing which one to choose can be difficult. If you’re ever in a position where you have to choose between stainless and galvanized steel, here’s what […]

Blog

Single-loop baling wire has many applications, but one fact remains the same no matter what it’s used for — it’s one of the most dependable products out there. If you’re thinking about picking up some single-loop baling wire, here’s a look at a couple of the reasons why so many people rely on it.

American steel is imported from all over the world, but the largest supplier of steel to the United States is, in fact, one of our neighbors. Contrary to the popular misconception that America was solely responsible for its own supply of steel up until the late 1970s, this close ally has been America’s number one […]

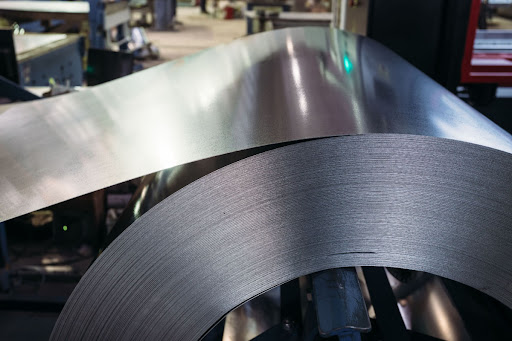

Today, galvanized steel has found widespread use in a vast array of industries and products. However, it’s a relatively new innovation in the grand scope of human history. The history of galvanized steel does not start with a single invention but was made possible by a series of scientific discoveries and experiments. Let’s take a […]

Plain carbon steel has been modified in many ways throughout the years to enhance its effectiveness, resulting in the creation of galvanized and stainless steel. These varieties have many advantages over normal steel, leading to their use in a wide range of products and appliances. While the two can be hard to distinguish at a […]

Given how many products use stainless steel wires, it is expected that the market for it can be an incredibly competitive landscape. From technological advancements in the industry to significant worldwide events, there are numerous stainless steel wire market trends. Here’s an overview of where the stainless steel wire market is headed in the future […]

The steel industry is a vital player in the world market, providing sheet steel for the factories of automotive corporations to make their cars, supplying steel so companies can create wiring, and much more. However, like with restaurants and other businesses, the coronavirus pandemic caused numerous problems for the steel industry.

If you need a way to make the wires your business uses tough and reliable, galvanization is the answer—galvanizing means applying a protective zinc coating to metal to help it resist damage. The name of the process originates from Luigi Galvani, an Italian physician who discovered electrical currents in animal tissue, which led to many […]

When it’s time to purchase new baling wire, it’s important to ensure that you know what to look for. Baling wire should be sturdy, reliable, and made from high-quality material. If you’re not sure how to tell if the steel wire you choose is fit for the job, we’re here to give you the answers […]

If you work in agriculture or the recycling industry, you understand the importance of baling wire. Baling wire allows you to move materials around easily. When you have the proper bale tie size, you save money, and it is less time wasted down the road.